|

Working pressure |

0-25bar |

|

Medium temperature |

-10℃~+180℃ |

|

Medium viscosity |

Max600cst(m㎡/s) |

|

ambient temperature |

-10℃~+70℃ |

|

body material |

SS304、316 |

|

Thread connection |

G1/2"~G3" |

|

Fluid range |

Corrosive fluids such as water, air, steam, acid, alkali, etc. |

|

control function |

Normally closed, normally open |

|

accessory |

Stroke limiter, emergency manual device, limit switch, solenoid valve |

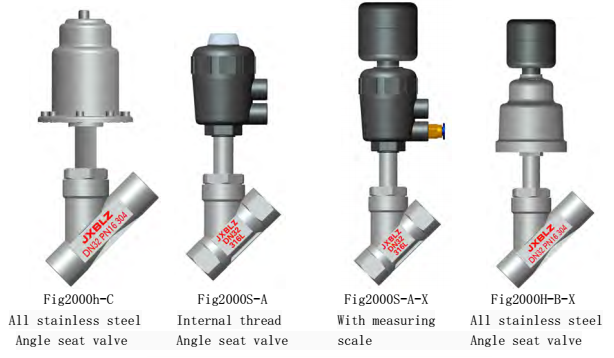

Product three dimensional diagram and structure diagram

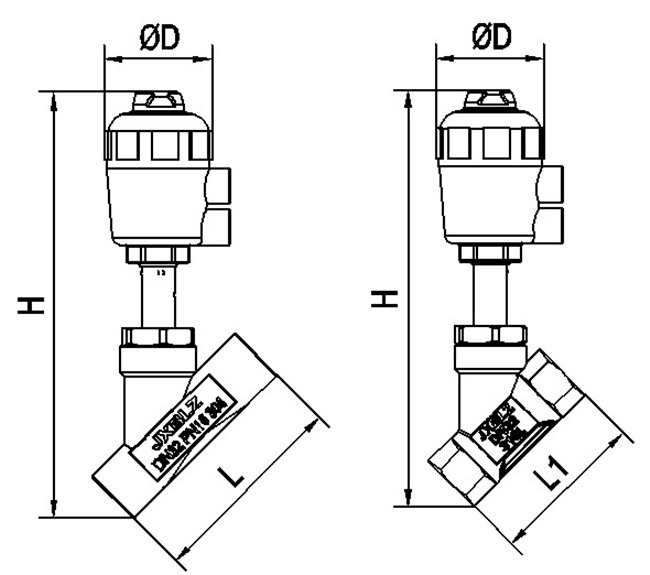

Main dimension

SIZE DN 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 internal diameter(mm) 10 10 13 18 23 30 36 46 60 L1 65 65 65 75 90 120 120 150 185 L 100 100 100 115 130 145 160 175 220 KV(m3/h) 3.6 3.6 4.9 8 19 27.5 42 52 90 Control gas source(MPa) min 0.3 0.3 0.3 0.4 0.4 0.4 0.4 0.4 0.4 max 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 Maximum working pressure(MPa) 0-1.5 0-1.5 0-1.5 0-1.5 0-1.5 0-1.5 0-1.5 0-1.5 0-1.5 Actuatorφ(mm) Φ50、Φ63、Φ80、Φ100、Φ125

|

Model |

description | |

|

JX2000 | ||

|

Connection type |

S |

Internal screw thread |

|

H |

welding | |

|

F |

flange | |

|

actuator |

A |

Plastic head cylinder |

|

B |

Stainless steel cylinder | |

|

Material type |

1 |

304 |

|

2 |

304L | |

|

3 |

316 | |

|

4 |

316L | |

|

Size |

DN |

DN15-DN100 |

|

Pressure |

PN |

PN0-PN16 |

|

Sample: | ||

Angle seat valve to maintain the flow rate can save space. It uses a spring with a single action to protect the safety of the operation of the steering angle seat valve.

Products made from stainless steel casting and Teflon, which can be used for most gases, liquids, steam and corrosive occasions. It carries a heat sink to protect the actuator. Ensure the valve has a long life span.

Angle seat valve’s principle and technical parameters:

Single and double action

Single action (pneumatic head is usually a hole); working principle; according to the spring reset to open and close the role, is divided into normally open and normally closed type.

double action (pneumatic head is usually two holes); working principle: to control the gas switch. (according to customer requirements, you can also choose to double acting and spring reset, more precise control).

characteristic:

1 with the valve open or closed position display.

2 external pneumatic pilot, can increase the service life, maintenance free.

3 overflow and the slide from the regulator gland, can improve the sealing performance.

4 body angle seat structure, can achieve large flow (in particular, compared with the general cut-off valve),

Compact fast response.

Installation and maintenance

1 piping must be clean and free from contamination.

2, according to the need to install, but the best to make the implementation of the agency. Pay attention to flow.

3 to connect the valve attention to the pipeline, only in the user's special requirements to take down the implementation of the agency.

4 open or repair the angle valve before the first cut off the fluid and control the gas source and reduce the pressure in the pipeline system.