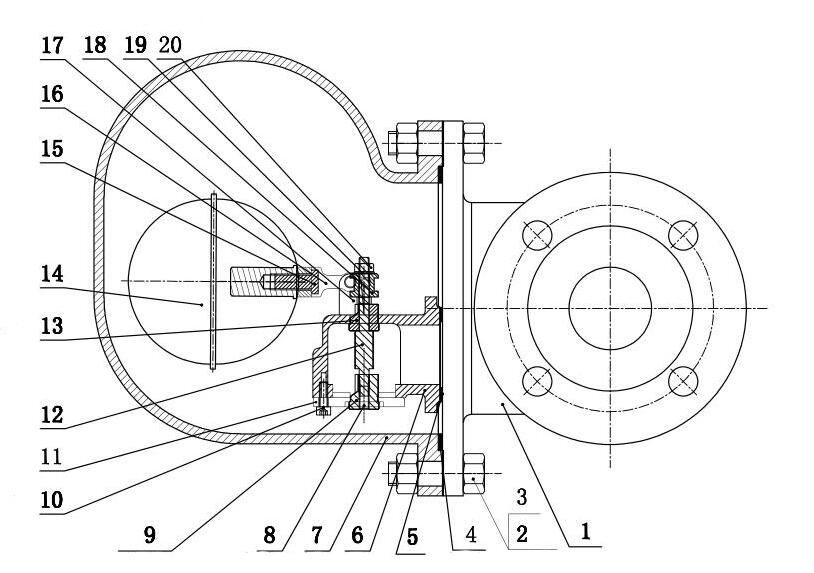

lever steam trap darwings

Spare parts and materials

No.

Spare parts

Materials

No.

Spare parts

Materials

1

valve body

WCB

11

support cap

304

2

Hexagon nut

35#

12

stem

304

3

hexagon bolt

35#

13

seal cover

304

4

PTFE

PTFE

14

float ball

304

5

PTFE

PTFE

15

hexagon bolt

304

6

support

304

16

Rotating block

304

7

bonnet

WCB

17

Limit block

304

8

Meter screws

304

18

Connecting block

304

9

Seal seat

304

19

Spring washer

304

10

inner hexagon screw

304

20

hexagon nut

304

|

Model |

DESCRIPTION | |||||

|

Valve type |

CS41H |

|

|

|

Free floating ball type | |

|

CS11H |

|

|

|

|

Free floating ball type | |

|

JX58H |

|

|

|

|

Lever float type | |

|

JX88H |

|

|

|

|

Inverted bucket | |

|

Connection type |

F |

|

|

|

Flange type | |

|

H1 |

|

|

|

Butt welding type | ||

|

H |

|

|

|

Plug in welding | ||

|

S |

|

|

|

Internal screw thread | ||

|

Size |

DN |

|

|

DN15-DN500 | ||

|

pressure |

PN |

|

PN10-PN64 | |||

|

LB |

|

150LB-600LB | ||||

|

K |

|

5K-40K | ||||

|

material |

WCB |

WCB | ||||

|

CF8 |

Stainless steel | |||||

|

Sample: | ||||||

Lever ball float type steam trap biggest advantage is not affected by pressure, temperature, condensation water flow fluctuations, continuous drainage, water line, the minimum temperature of 0 DEG C, can make the heating equipment to achieve the best efficiency; lever ball float type steam trap valve seat total in the level below, forming a water seal, no leakage of steam; the minimum working pressure 0.01Mpa, the maximum back pressure rate is less than or equal to 85%; with internal exhaust device, lever ball float type steam trap valve adopts the most advanced membrane components for automatic air discharge valve can automatically exclude non condensable gases, very sensitive, work quality is high, service life long. The trap design has balanced two seat structure, can achieve a large displacement of small size, especially for large heating equipment and heat transfer station equipment, gas drainage resistance, large heating equipment of choice for steam traps.

The use of double valve valve hole, the valve core in the valve opening pressure is relatively reduced, resulting in large displacement. When the change of the float with the liquid level of the valve cavity on the floating lever to open or close the valve seat. Because the seat seal hole is formed below the water level, water, natural gas separation, to no leakage of steam.