| Size | DN50-DN500mm |

| Nominal pressure | PN0.6-PN10MPa |

| Body | Straight through,Have a casting or forging steel parts |

| Connection | Flange ,weld |

|

No. |

Name |

Model |

Quantity |

Material |

|

a |

manual globe valve |

DN100/PN64 |

2 |

WCB |

|

b |

Flowmeter |

2 |

||

|

c |

Pressure transducer |

3 |

||

|

d |

Temperature gauge |

3 |

||

|

e |

Pneumatic pressure reducing valve |

DN100/PN64 |

1 |

WCB |

|

f |

reducing pipe |

DN100-DN150 |

1 |

|

|

g |

Steam pipe |

DN150 |

1 |

F1 |

|

h |

Spray device |

Φ25 |

3 |

WCB |

|

i |

Safety valve |

DN100/PN25 |

1 |

WCB |

|

j |

Check valve |

DN25/PN40 |

1 |

WCB |

|

k |

manual globe valve |

DN25/PN40 |

2 |

WCB |

|

L |

Temperature reducing valve |

DN25/PN40 |

1 |

WCB |

|

M |

manual globe valve |

DN25/PN40 |

1 |

WCB |

|

N |

Steam trap |

DN25/PN40 |

1 |

WCB |

|

P |

manual globe valve |

DN100/PN25 |

1 |

WCB |

|

Model |

Description | |

|

TYP800 |

|

|

|

Valve type |

TYP800 |

Split type |

|

TYP801 |

High side angle type | |

|

TYP802 |

High side Z type | |

|

TYP803 |

Integral type | |

|

Actuator |

A |

Single spring film type cylinder |

|

B |

Multi spring film type cylinder | |

|

C |

Piston type single acting cylinder | |

|

C1 |

Double acting cylinder | |

|

D |

Electric | |

|

G |

Gas-liquid dynamic | |

|

H |

Electro hydraulic power | |

|

Steam flow |

t/h |

Steam circulation tonnage per hour |

|

First grade steam pressure |

P1 |

P1<=10Mpa |

|

Second grade steam pressure |

P2 |

P2≤0.98MPa时,The change range of P2 is P2±0.4MPa; 0.98<P2≤3.82MPa时,The change range of P2 is P2±0.06MPa; P2>3.82MPa时,The change range of P2 is P2±0.15MPa。 |

|

First grade steam temperature |

t1 |

t1<=540℃ |

|

Second grade steam temperature |

t2 |

t2±4℃ |

|

Pressure relief valve diameter |

|

DN15-DN500 |

|

Temperature reducing valve diameter |

|

DN15-DN500 |

|

Outlet device diameter |

|

DN40-DN1000 |

|

remarks |

|

Other description |

|

Sample: Valve temperature 190 degrees Celsius, the pressure relief valve diameter DN25, the temperature valve diameter DN20, outlet device diameter DN50, cast steel material。 | ||

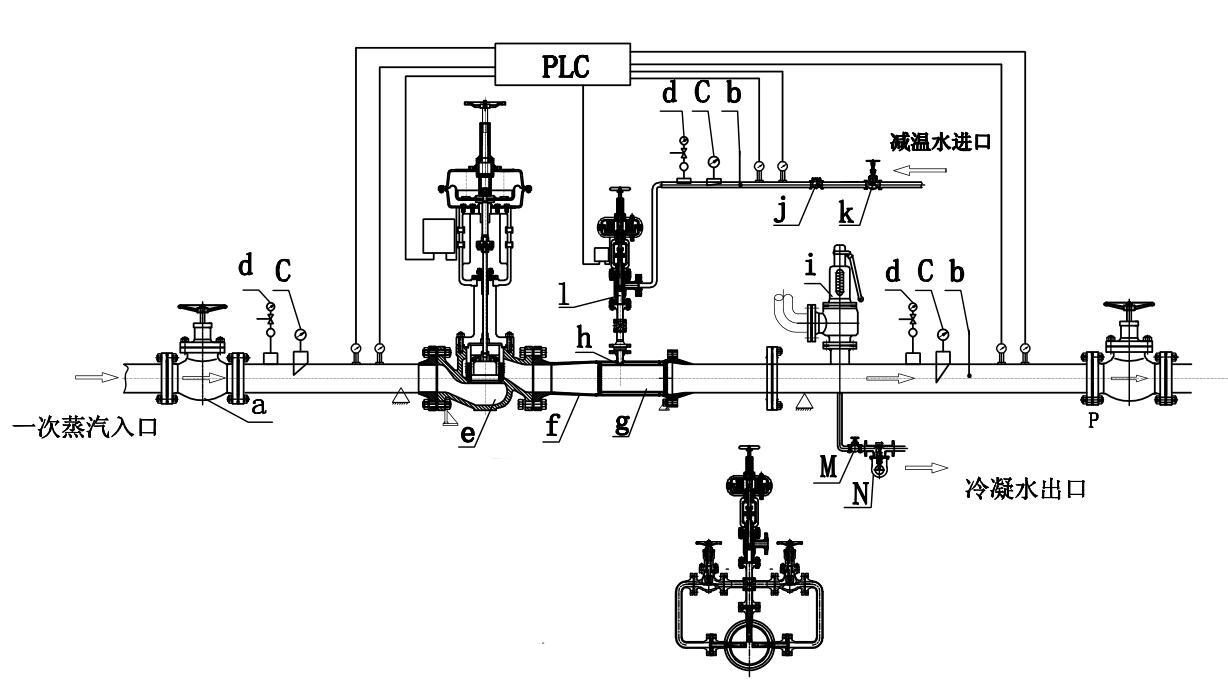

Desuperheating decompression device structure

Our company absorbed desuperheating decompression ‘s advanced technology and structure from foreign ,and developed such Desuperheating decompression device ,which is a new generation of products .It’s composed of 4 parts :pressure and temperature reducing valve, steam pipeline, attemperating water piping and thermal regulation device and etc.

Decompression , desuperheating and noise reduction, those three functions performe at one-stage in the valve body, which can avoid premature failure of components due to excessive temperature difference , in order to improve the service life of valve.

1、Steam pipe:

Due to the use of the pressure and temperature reducing valve, mixing pipe that sprays water to desuperheat separately in the original desuperheating decompression device is cancelled , which makes the whole device shortened about 1/2 length, compact structure, cover less area, reduce engineering investment. Pipe is installed with safety valve, pressure gauge, thermometer, etc. in order to ensure safe operation.

2、Warm water reduction system:

It’s composed of feed water regulating valve, check valve, globe valve and water supply pipeline, etc. Feed water regulator ‘s throttling element is cage sleeve or multistage throttle parts, can withstand high pressure difference, can avoid cavitation aroused when high pressure medium through the small gap, forming cavitation damage on the valve seat surface and throttling elements, and can reduce the leakage. Orifice is according to linear array, regulators with same diameter have different CV values to choose from, which can ensure precision and sensitivity.

3、The thermal control device:

It includes thermal control cabinet and electric actuator. Control mode according to the order need is divided into self-control (electronic monitoring instrument automatic control) and remote control. Automatic control cabinet includes: temperature display, pressure display, controller, alarm, operators, etc. Electric actuator used in pressure and temperature reducing valve and control valve is divided into straight travel and angular travel. Steam pressure transmitter can change steam pressure fluctuations into 4-20 m, current signal, the PI regulator conveys signals to electric execution unit driving pressure and temperature reducing valve, and then pressure is controlled. The regulation of steam temperature: thermal resistance(thermocouple)conveys 4-20 mA current signal to electric actuator through proportional integral differential unit and operator, driving feed water regulating valve to regulate the volume of water ,and then temperature is reduced.