|

Body | |

| Bore | DN15~DN500mm |

| Nominal pressure | PN16~PN420,5K~63K,150LB~2500LB |

| Applicable temperature | -196℃~+650℃ |

| Applicable medium | gas,water,oil,steam etc |

| Connection | flange,SW |

| Bonnet type | Normal type ,High temperature type, Bellows type , Low temperature type |

| Stuffing | PTFE,Flexible graphite |

| Seat | PTFE |

| Body material | WCB,WC6,WC9,CF8,CF8M,CF3M etc |

|

Trim | |

| Flow Characteristic | quick-open, equal percentage, Linear |

|

Actuator | |

| Type | Single spring diaphragm cylinder,multi-spring diaphragm cylinder,piston type/Double-acting cylinder,electric. |

|

Model |

Introduction | |

|

FIG681 |

||

|

Valve type |

TYP300 |

CV3000 type |

|

TYP900 |

forged steel sleeve type steam trap valve | |

|

TYP910 |

forged steel labyrinth control valve | |

|

TYP920 |

forged steel cascade throttle control valve | |

|

FIG580 |

2 ways control valve | |

|

FIG680 |

3 ways control valve | |

|

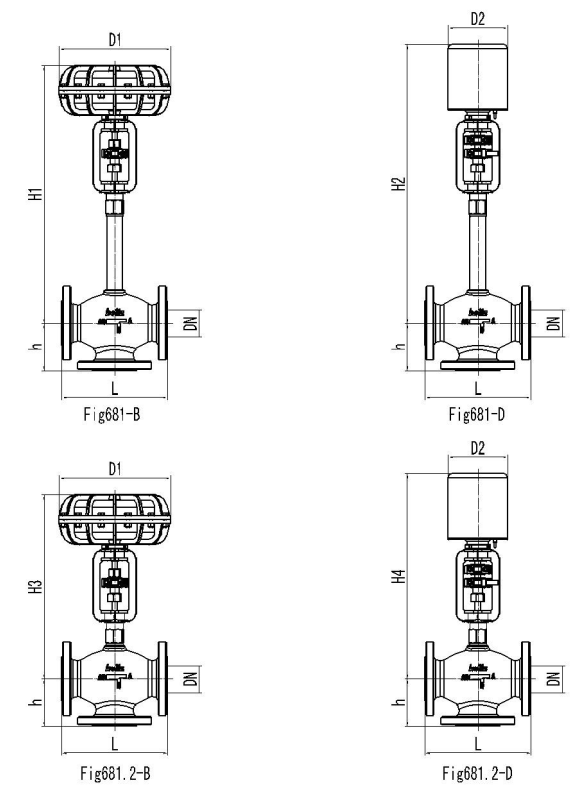

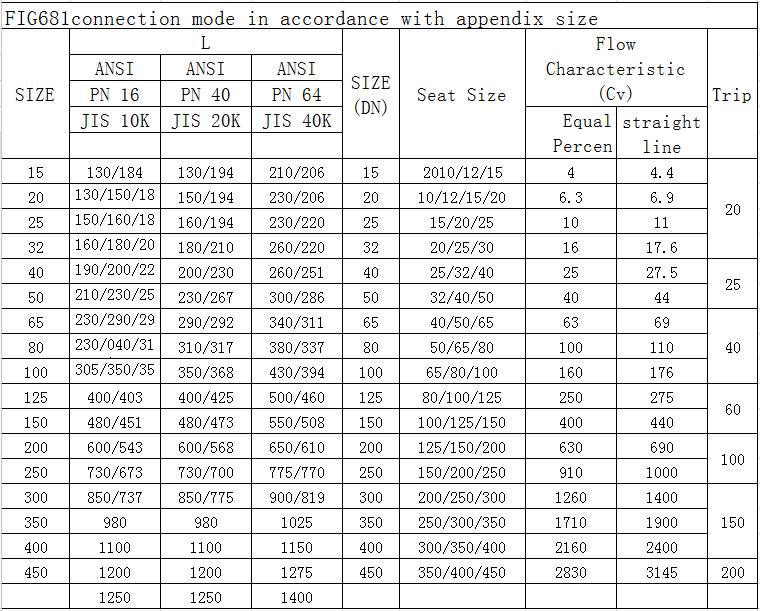

FIG681 |

3 ways bellows sealing control valve | |

|

JX480 |

slide valve | |

|

Actuator |

A |

single spring diaphragm type |

|

B |

multi-spring diaphragm type | |

|

C |

single action piston | |

|

C1 |

double action piston | |

|

D |

electric | |

|

F |

electric-hydraulic | |

|

E |

manual | |

|

G |

pneumatic-hydraulic | |

|

H |

other | |

|

Open/Close type |

1 |

air to open type |

|

2 |

air to close type | |

|

3 |

electricity to open | |

|

4 |

electricity to close | |

|

Action type |

A |

direct action |

|

B |

reaction | |

|

Handwheel |

1 |

without handwheel |

|

2 |

top mount the handwheel | |

|

3 |

Side mount the handwheel | |

|

Connection |

F |

flange |

|

H1 |

butt welding | |

|

H |

socket | |

|

S |

internal thread | |

|

S1 |

external thread | |

|

J |

wafer type | |

|

K |

other | |

|

Valve trim structure |

1 |

shut-off valve |

|

2 |

sleeve single seat valve | |

|

3 |

sleeve double seat valve | |

|

4 |

porous type noise reduction cage | |

|

5 |

labyrinth cage | |

|

6 |

multistage depressurization type cage | |

|

7 |

other | |

|

Valve core structure |

A |

balanced internal parts |

|

B |

unbalanced internal parts | |

|

Valve bonnet type |

1 |

standard type |

|

2 |

cooling fin type | |

|

3 |

lengthen type | |

|

4 |

bellow type | |

|

5 |

clamp cover type | |

|

6 |

other | |

|

Flow characteristic |

1 |

quick opening |

|

2 |

linear | |

|

3 |

equal percent | |

|

4 |

fixed percentage | |

|

Valve seat material |

1 |

RPTFE |

|

2 |

alloy steel | |

|

3 |

cemented carbide | |

|

4 |

tungsten steel | |

|

5 |

other | |

|

Norminal diameter |

DN |

DN15-DN500 |

|

Norminal pressure |

PN |

PN10-PN760 |

|

LB |

150LB-2500LB | |

|

K |

5K-60K | |

|

Material type |

1 |

WCB |

|

2 |

WC6 | |

|

3 |

WC9 | |

|

4 |

CF8 | |

|

5 |

CF3 | |

|

6 |

CF8M | |

|

7 |

CF3M | |

|

8 |

A105 | |

|

9 |

F91 | |

|

10 |

F22 | |

|

11 |

other | |

|

Illustraton | ||

|

1、TYP300-B-1-A-2-F-2-A-1-3-1-DN50-PN25-CF8 | ||

|

1.CV3000 series,Multi-spring diaphragm cylinder,air to open type,direct action,top mount the handwheel,sleeve single seat valve,balanced internal parts ,standard valve bonnet,equal percent type,RPTFE valve seat,norminal diameter DN50,norminal pressure PN25,CF8 material. | ||

Electric control valve is an important execution unit industrial in automation controlling process. As higher and higher degree of industrial automation, it’s being used more and more in the field of all kinds of industrial production. Compared with traditional pneumatic control valve, it has obvious advantages: energy-saving (only consume electricity when at work), environmental (no carbon emissions), convenient installation (no need for complicated pneumatic pipe and pump stations). According to its functions and features valve are divided into linear features, percentage and parabolic characteristics.

Working principle

Power supply:DC24V,AC220V,AC380V

Input control signal :DC4-20MA,DC1-5V

Feedback control signal:DC4-20MA(load (electric) hinder below 500Ω)

Automatic regulating function is realized by receiving signals (such as: 4 ~ 20 ma) from industrial automation control system to drive valve ,changing the cross-sectional area of the pipeline between valve core and valve seat ,controlling the flow rate, temperature, pressure and etc of pipeline medium.

New type electric control valve’s actuator has servo function, 4-20 ma, accepts unified 4-20mA or 1-5 v DC standard signal, converts current signal to corresponding linear displacement, automatically controls valve opening, achieving continuous adjustment to the fluid’s pressure, flow, temperature, liquid level and other process parameters inside the pipeline.

Electrical principle

Action principle: motor power 220 VAC or 380 VAC, control signal 4 ~ 20 mA, valve has controller inside, the controller converts current signal to the angular travel signal of the stepper motor, motor rotation, the straight travel or angular travel is realized by gears, levers, or gear lever driving the stem .

Feedback: motor operates through the gear running, slide rheostat outputs valve’s position signal by three joints, there are also three lines limit signals (full open and full closed. public line)