|

Body | |

| Size | DN15~DN500mm |

| Nominal pressure | PN16~PN420,5K~63K,150LB~2500LB |

| Applicable temperature | -196℃~+650℃ |

| Applicable medium | gas,water,oil,steam etc. |

| Connection | flange,SW |

| Bonnet type | Normal type ,High temperature type, Bellows type , Low temperature type |

| Stuffing | PTFE,Flexible graphite |

| Seat | PTFE |

| Body material | WCB,WC6,WC9,CF8,CF8M,CF3M etc |

|

Trim | |

| Flow Characteristic | quick-open, equal percentage, Linear |

|

Actuator | |

| Type | Single spring diaphragm cylinder,multi-spring diaphragm cylinder,piston type/Double-acting cylinder,electric |

)

|

Model |

Introduction | |

|

FIG680 |

||

|

Valve type |

TYP300 |

CV3000 type |

|

TYP900 |

forged steel sleeve type steam trap valve | |

|

TYP910 |

forged steel labyrinth control valve | |

|

TYP920 |

forged steel cascade throttle control valve | |

|

FIG580 |

2 ways control valve | |

|

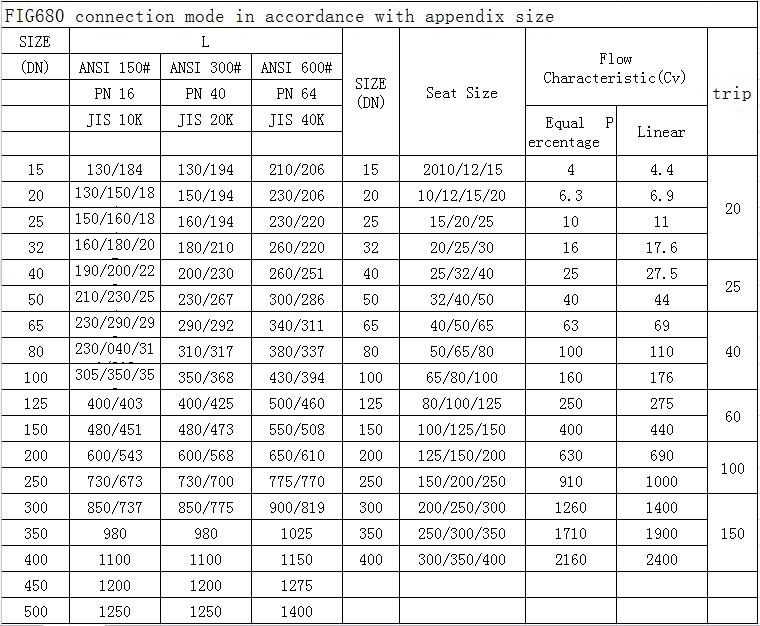

FIG680 |

3 ways control valve | |

|

FIG681 |

3 ways bellows sealing control valve | |

|

JX480 |

slide valve | |

|

Actuator |

A |

single spring diaphragm type |

|

B |

multi-spring diaphragm type | |

|

C |

single action piston | |

|

C1 |

double action piston | |

|

D |

electric | |

|

F |

electric-hydraulic | |

|

E |

manual | |

|

G |

pneumatic-hydraulic | |

|

H |

other | |

|

Open/Close type |

1 |

air to open type |

|

2 |

air to close type | |

|

3 |

electricity to open | |

|

4 |

electricity to close | |

|

Action type |

A |

direct action |

|

B |

reaction | |

|

Handwheel |

1 |

without handwheel |

|

2 |

top mount the handwheel | |

|

3 |

Side mount the handwheel | |

|

Connection |

F |

flange |

|

H1 |

butt welding | |

|

H |

socket | |

|

S |

internal thread | |

|

S1 |

external thread | |

|

J |

wafer type | |

|

K |

other | |

|

Valve trim structure |

1 |

shut-off valve |

|

2 |

sleeve single seat valve | |

|

3 |

sleeve double seat valve | |

|

4 |

porous type noise reduction cage | |

|

5 |

labyrinth cage | |

|

6 |

multistage depressurization type cage | |

|

7 |

other | |

|

Valve core structure |

A |

balanced internal parts |

|

B |

unbalanced internal parts | |

|

Valve bonnet type |

1 |

standard type |

|

2 |

cooling fin type | |

|

3 |

lengthen type | |

|

4 |

bellow type | |

|

5 |

clamp cover type | |

|

6 |

other | |

|

Flow characteristic |

1 |

quick opening |

|

2 |

linear | |

|

3 |

equal percent | |

|

4 |

fixed percentage | |

|

Valve seat material |

1 |

RPTFE |

|

2 |

alloy steel | |

|

3 |

cemented carbide | |

|

4 |

tungsten steel | |

|

5 |

other | |

|

Norminal diameter |

DN |

DN15-DN500 |

|

Norminal pressure |

PN |

PN10-PN760 |

|

LB |

150LB-2500LB | |

|

K |

5K-60K | |

|

Material type |

1 |

WCB |

|

2 |

WC6 | |

|

3 |

WC9 | |

|

4 |

CF8 | |

|

5 |

CF3 | |

|

6 |

CF8M | |

|

7 |

CF3M | |

|

8 |

A105 | |

|

9 |

F91 | |

|

10 |

F22 | |

|

11 |

other | |

|

Illustraton | ||

|

1、TYP300-B-1-A-2-F-2-A-1-3-1-DN50-PN25-CF8 | ||

|

1.CV3000 series,Multi-spring diaphragm cylinder,air to open type,direct action,top mount the handwheel,sleeve single seat valve,balanced internal parts ,standard valve bonnet,equal percent type,RPTFE valve seat,norminal diameter DN50,norminal pressure PN25,CF8 material. | ||

Pneumatic control valve drives itself by compressed air as power source , cylinder as actuator and with some attachments ,such as electric-pneumatic positioned、converter、 solenoid valve、lock up valve and so on. It realizes the switch quantity or proportional adjustment, and receives the control signal of industrial automation control system to complete regulating the flow 、pressure 、temperature and other various process parameters of pipeline medium. Pneumatic control valve has characteristics of simple controlling, quick response, and intrinsically safe without additional explosion prevention measure.

Pneumatic control valve’s actions are divided into Air to open type and Air to close type. Air to open type is that when the air pressure on membrane head increases, valve moves in the direction of opening increasing; until it reaches to input pressure limit, the valve is in the fully open position. In reverse, when the air pressure is reduced, valve moves in the direction of closing, when there is no input air, the valve is fully closed.

So sometimes, Air to open type is also called Fail to Close/ FC type. Air to close type‘s movement direction is just the reverse of Air to open type. When the air pressure increases, valve moves in the direction of closing; when air pressure decreases or disappears, valve moves in the direction of opening or until fully open. So sometimes it’s called Fail to Open /FO. Pneumatic control valve belongs to which type is according to positive and negative effects of the actuator and different assemble ways of valve structure.

Choosing Air to open or Air to close is according to safety perspective of the process of production. When cut off the air source, in the closed position or open position control valve is safe?

For example, a heating furnace combustion control, the control valve is installed in the fuel pipe, according to the temperature of furnace or the heated material in furnace exit to control the supply of fuel. At this time, Air to open type valve is safer, because once stop the air supply, It’s more suitable in closed position than in fully open position for valve.

If air supply is cut off, fuel valve is fully open, risk will appear because of excessive heating. And such as a cooling heat-exchange equipment with cooling water, hot material in the heat exchanger are cooled when having heat exchange with cooling water, control valve is installed on the cooling water pipe, temperature of heat exchanged materials is used to control the cooling water’s volume, when the air supply is cut off, control valve in open position is more safe, Air to close type is appropriate.

Valve positioner is the main accessory of control valve, it accepts the regulator output signal, and then controls the pneumatic control valve by its output signal, when control valve moves, the displacement of valve stem feedback to valve positioner through mechanical device, valve position condition will be sent o the upper system through the electrical signal .

According to valve positioner structure and working principle ,it can be divided into pneumatic valve positioner, electric-pneumatic valve positioner and smart valve positioner.

Valve positioner can increase the output power of control valve, reduce the transmission lag of control signal, speed up movement of valve stem, improve the linearity of valve, overcome the friction of valve stem and eliminate the influence of unbalanced force, so as to ensure positioning rightly.

valve positioner

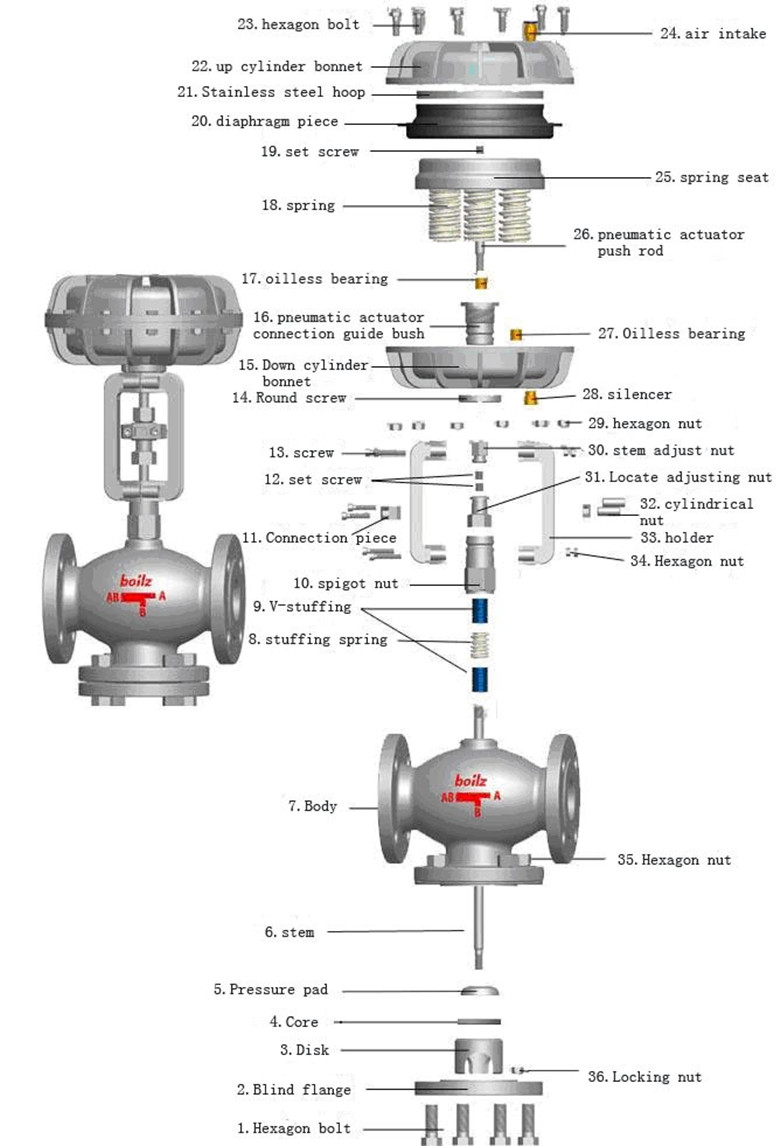

Actuator has pneumatic actuator, electric actuator, straight stroke and stroke.